NARDO IN BRIEF

We are a metal casting company with gravity casting and sand-cast processes with a capacity ranging from 1 kg to 4000 kg per part, with a monthly volume of 4,000 parts.

Our facilities have 5 induction furnaces and 2 cupola furnaces, as well as sand, chemical, metallographic and mechanical laboratories.

We use simulation software for casting and ISO 9001:2015 Quality Management Systems Certificate.

We fabricate patterns in wood, aluminum, resins and styropor, beginning from physical samples, 2D drawings and 3D files.

We offer 3D scanning in the field and in our facilities, in addition to measurement guarantees at customer request via CMM measurement.

FUNDICIONES NARDO SERVICES

MACHINING

FOUNDRY SERVICES

We have a wide variety of induction furnaces, which allows us to supply both medium production volumes (2000 to 4000 parts) and low volumes (5 to 100 parts).

FOUNDRY PATTERNS

We work with patterns in wood, aluminum, epoxy resin and styropor, the latter which is used to make parts that will only be manufactured once.

WEIGHT CALCULATOR

OUR MATERIALS

CARBON STEEL CASTING

STAINLESS STEEL CASTING

REFRACTORY STEEL CASTING

MANGANESE STEEL CASTING

DUCTILE IRON CASTING

GRAY IRON CASTING

ALUMINIUM ALLOY CASTING

SPECIAL ALLOY CASTING

STANDARS

ISO 8062

ASTM

ASTM International standards are used for research and development projects, quality systems, product testing and acceptance, and business transactions worldwide. These are an integral component of today’s competitive business strategies.

MPSS

Quality standards for steel castings for valves, flanges, fittings, and other piping components; visual methodology for the evaluation of surface irregularities.

Innovation

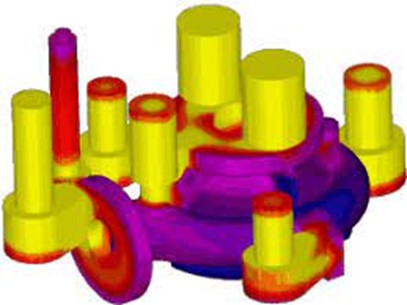

SolidCast® 8.0 is a technological program used as a tool for casting design and simulation. The program especially focuses on the solidification and cooling of casting metal and its behavior in part specifications.

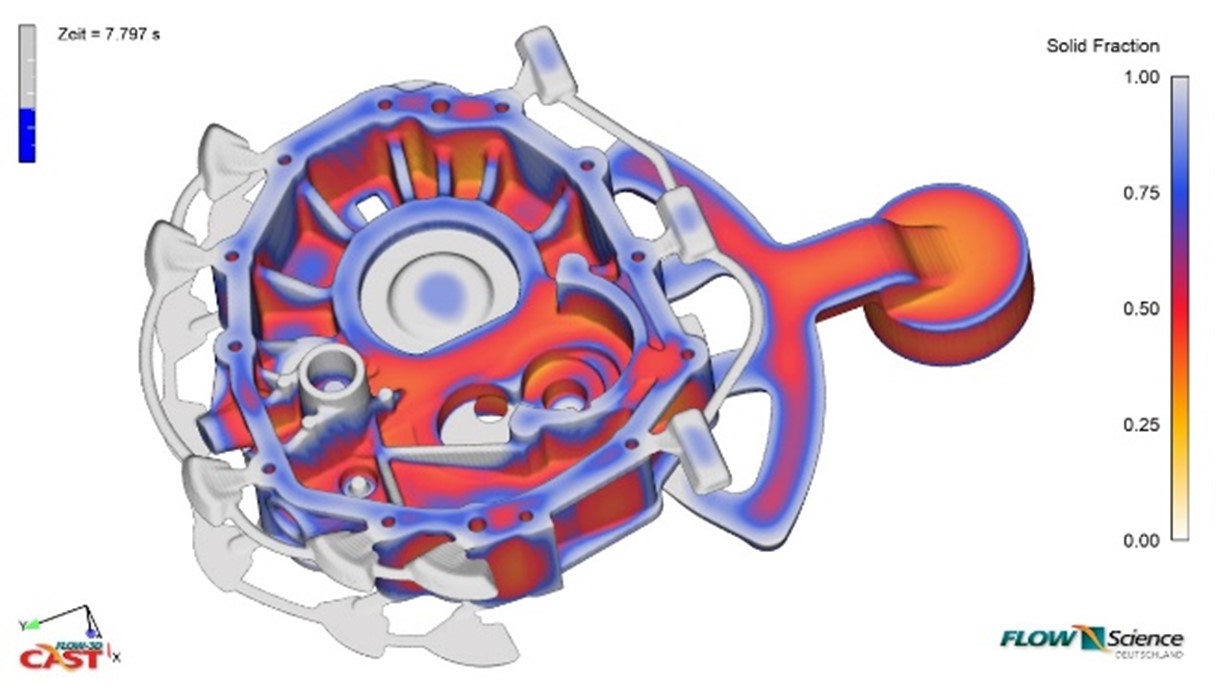

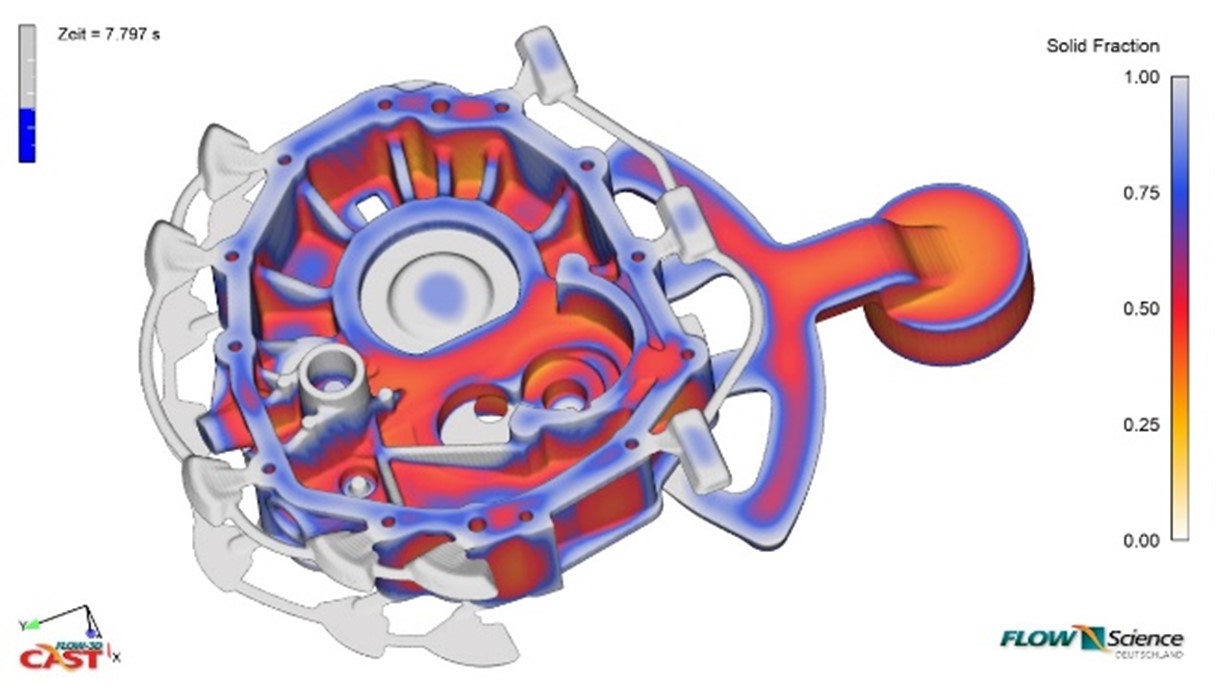

FLOW-3D Cast is a simulation software specifically designed for casting process modeling. The program provides engineers and designers with highly accurate results of metal dynamics and solidification.

NOVEDADES

FLOW-3D Cast is a simulation software specifically designed for casting process modeling. The program provides engineers and designers with highly accurate results of metal dynamics and solidification.

SECTORS WE

SERVICE

Mining

Paper Industry

Petrochemicals

Refacciones

Water Systems

Telecom

Transport

Heat Treatment

Metro Industry

Valve Manufacturing

Food

Automotive

Sugar

Cemetery

Construction

Electrical

Railway

Harbor Infrastructure

Maritime

ES

ES